| Product Name | Magnesium Ingots | |

| Standard | ASTM B93/B93M , ISO 16220, GB/T 3499-2018, JIS H 4000, AMS 4377G | |

| Mg9999, Mg9998, Mg9995A/B, Mg9990, Mg9980 | ||

| Purity | >99.9% | |

| Color | Silvery white | |

| Alloy | Non-alloy | |

| Shape | Square | |

| Density | 1.738 g/cm³ | |

| Melting point | 650°C (Pure magnesium) | |

| Sample | Available for free | |

| Export Region | America , Canada ,Japan , England , Saudi Arab , India , Singapore , Korea , Australia , Brazil , Argentina , Mexico , Russia , Turkey , France , Germany , Spain etc. | |

| Payment | T/T , L/C , West Union | |

| Delivery time | 10-30 days subject to the clients' requirement and quantity | |

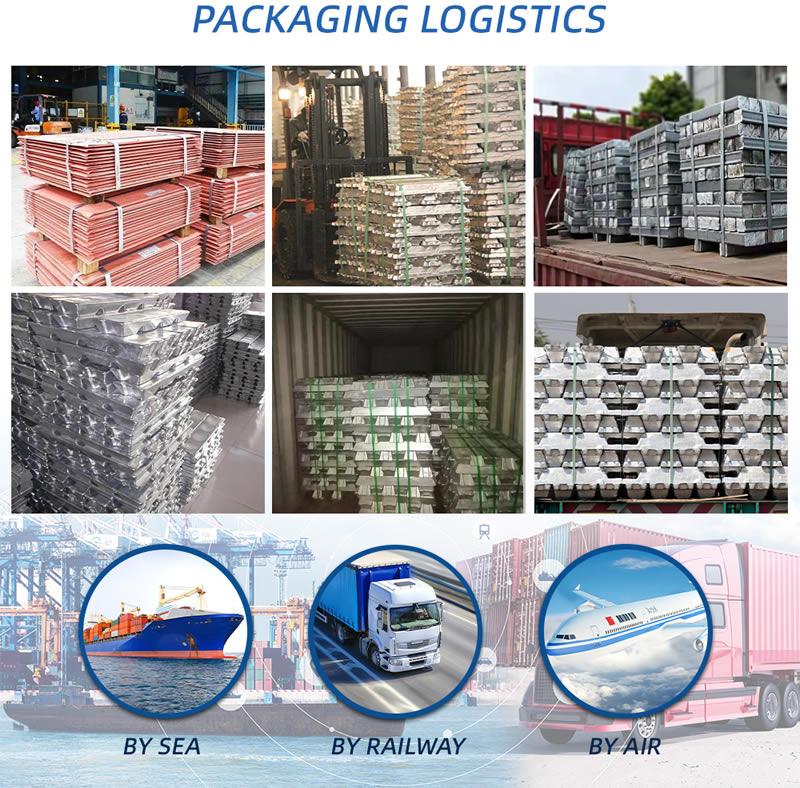

| Package | clients' requirement and Standard export sea-worthy packing | |

| MOQ | 1 ton | |

The density of magnesium is 1.74g/cm3 which is even lighter than aluminum 2.7g/cm3, but mechanical strength and chemical stability are much better than aluminum.

* When magnesium ingots are exposed to air, they may initially appear silver white or slightly yellow in color. Over time, a magnesium oxide layer will gradually form, and the color of the magnesium ingot may change to gray, gray black, or even dark gray.

* Magnesium can be directly related to nitrogen, sulfur and halogen such as chemical combination, including hydrocarbons, aldehydes, alcohols, phenols, amines, grease and most of the oil pharmaceutical.

Chemical Analysis

| Designation | Chemical compositions % | |||||||||||

Mg≥ | Fe≤ | Si≤ | Ni≤ | Cu≤ | Al≤ | Mn≤ | Ti≤ | Pb≤ | Sn≤ | Zn≤ | Other | |

Mg9999 | 99.99 | 0.002 | 0.002 | 0.0003 | 0.002 | 0.002 | 0.002 | 0.0005 | 0.001 | 0.002 | 0.003 | - |

Mg9998 | 99.98 | 0.002 | 0.003 | 0.0005 | 0.004 | 0.004 | 0.002 | 0.001 | 0.001 | 0.004 | 0.004 | - |

Mg9995 A | 99.95 | 0.003 | 0.006 | 0.001 | 0.002 | 0.008 | 0.006 | - | 0.005 | 0.005 | 0.005 | 0.005 |

Mg9995 B | 99.95 | 0.005 | 0.015 | 0.001 | 0.002 | 0.015 | 0.015 | - | 0.005 | 0.005 | 0.01 | 0.01 |

Mg9990 | 99.90 | 0.04 | 0.03 | 0.001 | 0.004 | 0.02 | 0.03 | - | - | - | - | 0.01 |

Mg9980 | 99.80 | 0.05 | 0.05 | 0.002 | 0.02 | 0.05 | 0.05 | - | - | - | - | 0.05 |

Cd,Hg,As,Cr6+ element,The supplier does not make routine analysis, but should monitor its content,require ω(Cd+Hg+As+Cr)≤0.03%. | ||||||||||||

Applications

1.Magnesium alloys can be used to manufacture aircraft fuselages,engine parts, etc.

2.As strong reducing agent for titanium, zirconium, beryllium, uranium and hafnium production.

3.Magnesium metal is the main alloying element in aluminum alloy

4.Magnesium powder can be used as desulfurizer for steel making.

5.Magnesium also used to make photography and optical instruments, etc.

6.Can be used to produce magnesium fertilizer, promote the absorption and utilization of phosphorus by plants.

7.As an additive agent in conventional propellants and the production of nodular graphite in cast iron.